Welcome To

SHAMO PLAST

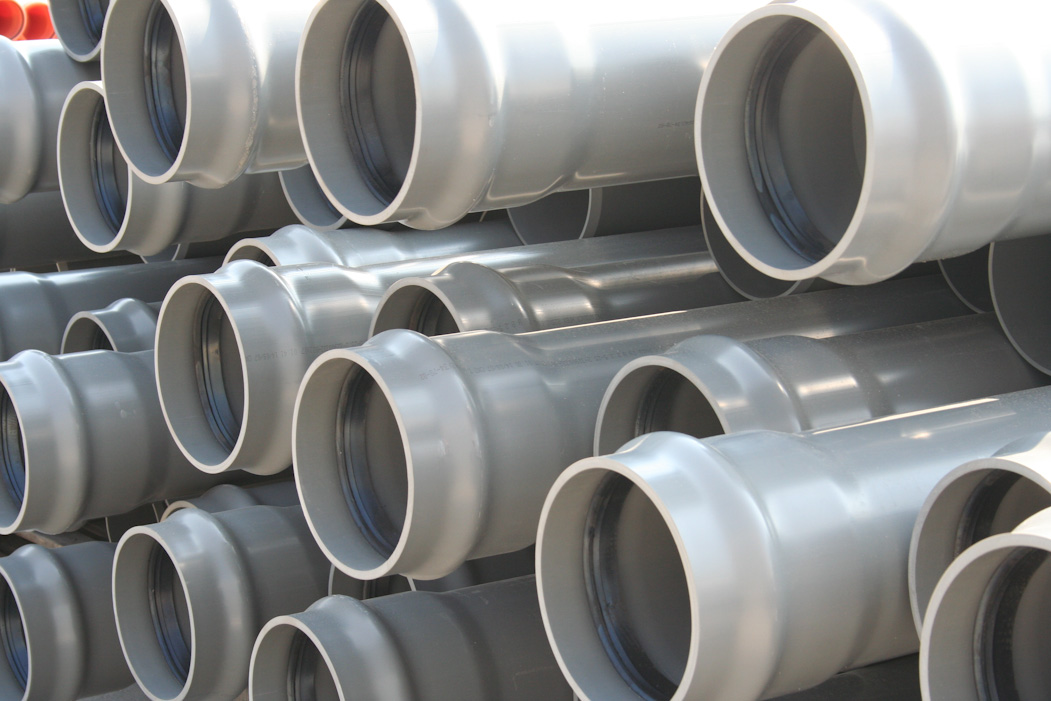

Established in the year 1995, SHAMO PLAST INDUSTRIES LLC has been a pioneering industry in the

United Arab Emirates to manufacture UPVC pipes and Pressure pipes and PPR pipes for sewer drain,

Telephone & Electrical Conduit.

View Our

PRESSURE PIPE SYSTEMS

UPVC pressure pipes from size ½” to 16”(20mm – 400mm) in the major International Standards – BS, BS EN,

ASTM, DIN, ISO, NF. ShamoPlast pressure pipe is used in town water supply, irrigation networks, high rise buildings, domestic dwelling, mining and industrial applications. Pipe can be supplied with rubber ring or solvent socket jointing system.

View Our

DUCT AND CONDUIT PIPE

Shamo Plast produces uPVC Duct Pipes long-lasting, cost-effective solutions for industrial and

institutional corrosive fume exhaust, drain applications for electrical cable. A range of upvc

schedule 40 ducts in sizes 1/2″ to 6″ that are in accordance with NEMA TC-2A standard

View Our

PPR PIPES

Shamoplast PP-R pipes & fittings are manufactured according to German standards with sizes ranging

from 20mm up to 110mm. Hot and cold potable water piping networks in residential and commercial

buildings. The outstanding temperature rating up to 95°C and pressure rating PN 20 make PP-R system

View Our

UNDERGROUND DRAINAGE PIPE

Shamo Plast produces a range of UPVC pipes for above and below ground use made from 100% virgin

UPVC. It has a full range of fittings in both solvent weld and rubber ring joint for all sizes. The

are produced in all the major international standards ie: European Standards BS EN 1401, BS EN 1329,

Established in the year 1995, SHAMO PLAST INDUSTRIES LLC, has been a pioneering industry in the United Arab Emirates to manufacturer UPVC pipes and Fittings, BS-EN Standard and DIN Standard for Pressure pipes sewer drain, drainage, water purpose, Telephone Duct, Electrical Conduit Pipe and PPR Pipe for HOT and COLD Water and other international standards in order to become the best alternative cheaper, more efficient, easy to transport to site, easy to install and resistant to corrosion and chemicals. In our modern lifestyle UPVC pipes are a better technical solution. It belongs to SHAMO GROUP OF INDUSTRIES, which is one of the largest and most diversified business conglomerates in the middle east & African countries

Projects Financed

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam.

Shamo Plast Products

Pressure Pipe System

Shamo Plast produces a wide range of UPVC Pressure Pipes to most of the major international standards and dimensions of Metric and Imperial. The pipes are made from 100% virgin UPVC resin and have a minimum required strength MRS=25 mpa so that the pipes meet or exceed the rigorous hydrostatic requirements of the standards. The

Pressure Fittings

A full range of UPVC and CPVC fittings to the main International Standards of EN1452, BS3505, DIN8063 and ASTM D2466 including sizes from 1/2”-16” (16mm- 400mm). The fittings include solvent weld joints and are fully compatible to the Shamo Plast pipe range. Specially fabricated fittings and long radius bends can be supplied on

UPVC Drainage Pipe System

Shamo Plast produces a range of UPVC pipes for above and below ground use made from 100% virgin UPVC. It has full range of fittings in both solvent weld and rubber ring joint for all sizes. The pipes are produced in all the major international standards ie: European Standards BS EN 1401, BS EN 1329, as well as the previous

Drainage Fittings

UPVC drainage fittings in either British or Metric / ISO dimensions from size 1 1/4″ to 16″ (36mm – 400mm). The fittings are suitable for all drain applications including soil, waste, underground and gravity sewer systems. Fittings can be supplied with either rubber ring or solvent socket weld jointing systems. Fittings are available in light grey

Duct and Conduit Pipe System

Shamo Plast produces a range of upvc schedule 40 ducts in sizes 1/2″ to 6″ that are in accordance with BRITISH standard and listed to BS 6099. The conduits are suitable for above or below ground installations and made from 100% virgin pvc resin. The ducts meet and exceed all the mechanical and performance requirement of both the

PPR Pipe and Fittings System

Shamo Plast PP-R pipes & fittings are manufactured according to German DIN standards with sizes ranging from 20mm upto 160mm. Hot and cold potable water piping networks in residential and commercial buildings. The outstanding temperature rating up to 95°C and pressure rating up tp 20 Bar make PP-R system

Polyethylene Pipe System

HDPE, LDPE and LLDPE pipe systems in a range of sizes and specifications from 1/2″ to 4″ (13mm – 110mm). Polyethylene pipe is used for water supply, irrigation systems, plumbing connections, gas distribution and drainage. A full range of insert electrofusion, butt welded and compression fittings to suit all Shamo Plast

Quality0%

Commitment0%

Client Satisfaction0%

OUR POLICY

The Quality policy of ‘SHAMO PLAST’ is committed to supply of high Quality of Product to the complete satisfaction of each and every customer and thus achieve leadership in market as a reputed and reliable supplier.

To achieve this goal, we shall continuously pursue these Objectives.

- Review the effectiveness of the Quality Management System at frequent intervals

- Providing best quality product on time.

- Achieving high degree of product consistency.

- Update the system to suit the changing need of the customers as well as technology changes.

- Committed to continues improvement in both materials, and quality control with the ultimate aim of providing zero defects.

![]](https://shamoplast.com/wp-content/uploads/2015/05/image-2.jpg)